Getting Zone and Class/division Markings in North America for IECEx Certified Products

IECEx is the only certification system available globally for equipment used in explosive atmospheres. Although IECEx certification is not accepted as valid for European countries or North America (except by the US Coast Guard), IECEx, and the relevant Standards, were established in such a way as to facilitate international trade in electrical equipment for use in explosive atmospheres. (Ex). The testing requirements for an IECEx certificate are recognized globally as forming the basis of other certifications around the world. It is in manufacturers’ best interests to obtain North American certification for their IECEx certified products, making them competitive in the North American marketplace.

Products with IECEx markings have already been assessed to meet the requirements of the IEC zone system. Armed with the correct information, and with some additional effort, manufacturers of these certified products can then achieve the zone-based markings required for their products to be exported to North America. Assessment and approval of products for use in North America must be done by an authorized certifying body in Canada and/or the US. In Canada, the Standards Council of Canada (SCC) accredits certifying agencies (e.g., CSA Group, QPS, UL and FM Approvals). In the US, certifying agencies are accredited by the OSHA. Certifying agencies in North America ensure that the devices comply with relevant North American Standards that ensure their safety. Accredited agencies for both Canada and the USA can provide valid certificates that are accepted in both countries.

Products with IECEx markings have already been assessed to meet the requirements of the IEC zone system. Armed with the correct information, and with some additional effort, manufacturers of these certified products can then achieve the zone-based markings required for their products to be exported to North America. Assessment and approval of products for use in North America must be done by an authorized certifying body in Canada and/or the US. In Canada, the Standards Council of Canada (SCC) accredits certifying agencies (e.g., CSA Group, QPS, UL and FM Approvals). In the US, certifying agencies are accredited by the OSHA. Certifying agencies in North America ensure that the devices comply with relevant North American Standards that ensure their safety. Accredited agencies for both Canada and the USA can provide valid certificates that are accepted in both countries.

There are two main additional requirements for IECEx certified products to be certified in North America’s zone system: compliance with general safety, also called “ordinary location” requirements, and “national deviations” requirements. Ordinary location requirements are specific for each type of electrical equipment and cover general safety requirements such as risk of electrical shock, fire hazards and injuries. Different types of electrical equipment have their own ordinary location Standards. For instance, process control equipment must comply with CSA C22.2 no 61010-1 or CSA C22.2 no 142 for Canada and with UL 61010-1 or UL 916 for the USA. Electrical motors and generators must comply with CSA C22.2 No. 100 for Canada and UL 1004 for the USA. The full list of equipment types and the ordinary location Standards that apply to them may be found in the Canadian Electrical Code (CEC) and the National Electrical Code (NEC) of the U.S.

After a product has been assessed to ensure compliance with general safety Standards, it then needs to meet the hazardous location National Deviation requirements for zone marking, based on the original IECEx certificate. The Standards that clarify these National Deviations are the CSA/UL 60079 series, which were crafted to be identical to the IEC 60079 series, but with some additional national deviations. For instance, Standards CSA C22.2 No. 60079-0 and UL 60079-0 are similar to IEC 60079-0 in the core section, but there are some additional modifications or requirements in some clauses, added in order to meet the requirements of North America.

After IECEx products have been proven to comply with both Ordinary Locations Standards and National Deviations related to hazardous locations, a North American certificate is generated. An additional, final requirement is a quarterly factory inspection conducted by the certification agency issuing the Certificate.

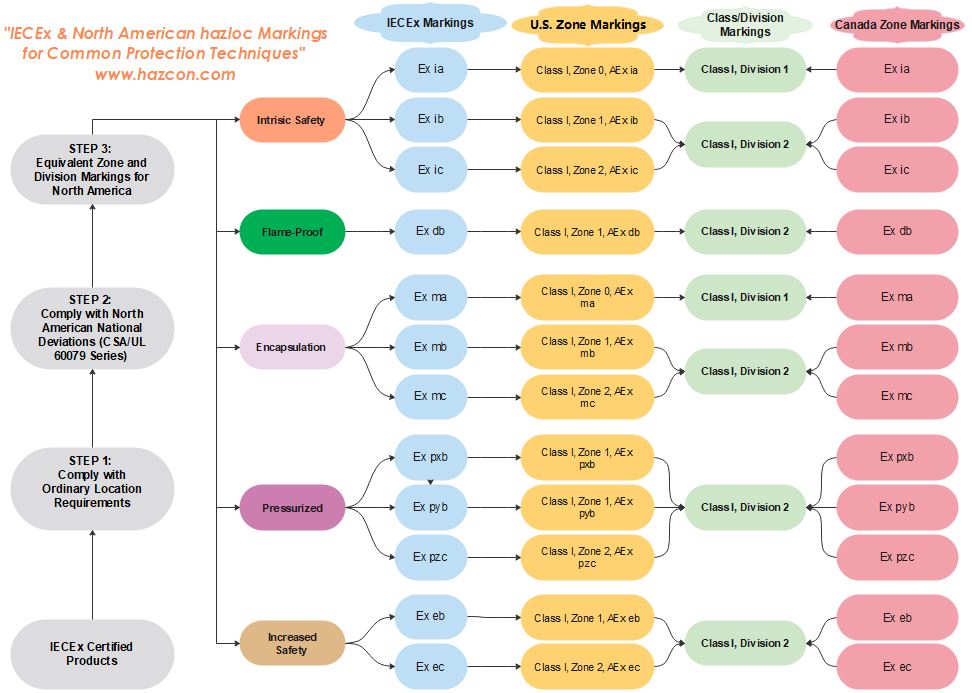

Consider that the IECEx certification system is a zone-based system. North America also has a zone-based certification system. The information noted in this article addresses gaining a North American zone system certification. Keep in mind that North America also has a Class/division system (unique to North America). Manufacturers of products that already have an IECEx certification may therefore choose to seek a zone-based certification for North America, as has been described in this article, and a Class/division certification. Those manufacturers seeking any Class/division certification, if they do not have IECEx certificate for their products, will need to start from scratch to obtain it. Manufacturers who already have IECEx certificate may obtain an equivalent Class/Division marking after they comply with all the requirements described in this article.

Zone markings for products with an IECEx certification refer to protection technique(s), Gas groups/ Dust Groups, T-class, and equipment protection level. An example of IECEx marking is this:

Ex db IIC T4 Gb

- Ex: Means explosion protected

- db: Refers to the protection technique (Explosion proof; other possibilities include Intrinsic safety (i), increased Safety (e), Purged and pressurized (p), and so on

- IIC: Gas group (Acetylene and Hydrogen; other options can be IIB (Ethylene) and IIA (Propane)

- T4: Temperature Class; temperature classes can be T1, T2, T3, T4, T5 or T6

- Gb: Equipment Protection Level for Zone 1; this can also be Ga (For zone 0) and Gc (for Zone 2)

Products approved for use in North American must also bear the label of the North American certifying body (e.g., QPS, CSA) and any additional markings related to the relevant North American Standards for the product.

The graph below compares IECEx markings and North American markings for Ex products, given commonly used protection techniques.

As was already noted, it is often in manufacturers’ best interests to bring their IECEx-certified products to the North American market. To do so, they need to seek North American certification. If they choose a zone-based certification, and with some guidance, this process is relatively straightforward. Class/Division marking is also achievable. Hazcon Inc. recommends dual marking in North America (zone marking and Class/division marking) in order to remain competitive.

Request a Consultation

Complete the form below to get started.