Field Service Software Solution

Efficient Software Solution to the Inspection and Maintenance of Electrical Equipment in Hazardous Locations

Special Attention Required in Hazardous Locations

Hazardous locations require electrical devices to be carefully designed to render them safe for use in such environments. Protective measures reduce the risk of explosion, environmental damage, injury, and especially fatalities in these hazardous atmospheres. The integrity of these protective features must be preserved throughout the equipment’s lifetime. Risks are present in these environments that, over time, adversely affect those same safety features. For all these reasons, regularly scheduled inspections are required to monitor equipment and prevent equipment failure. These inspections must be linked to a proper preventative maintenance plan.

Normal ‘wear and tear ‘is expected in any environment. In a hazardous location, such deterioration (seals becoming brittle, for example) can significantly reduce the degree of protection. Other kinds of deterioration might also be expected, given the nature of the environment (the introduction of chemicals or explosive materials, for example). The safety features of electrical devices installed within hazardous environments can’t be expected to remain as they were on installation. The progressive degradation of safety features must be carefully monitored!

Consequences of Failure to Conduct Proper Inspections and Routine Maintenance

The lack of ongoing, regularly scheduled inspections may contribute to equipment breakdown, environmental damage, plant shutdown, injury, fatalities, and a ruined reputation. These outcomes must be anticipated and managed: detailed inspections must be conducted and their findings tracked. A proper maintenance plan must be in place, considering the specific protective features of the equipment installed. These actions, appropriately done, contribute to ensuring the ongoing compliance of the device with relevant Standards and Codes.

An Efficient Digital Solution

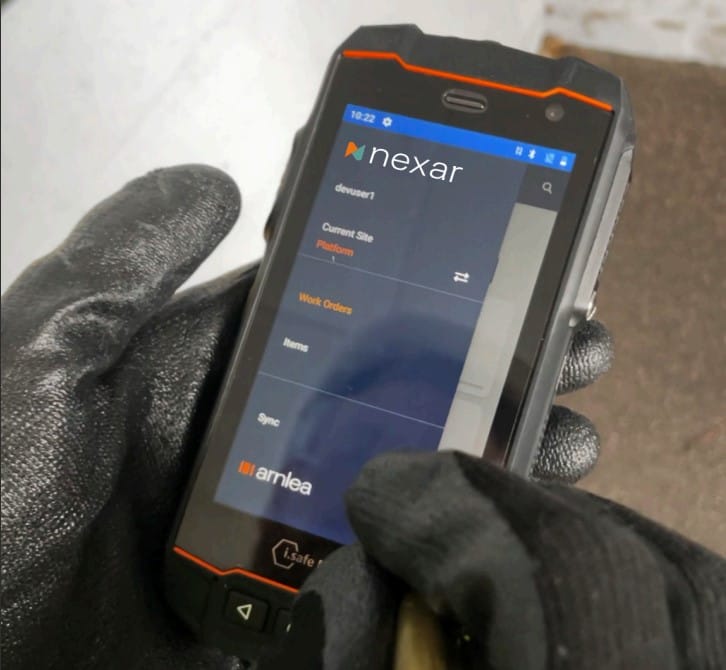

Hazcon has partnered with Arnlea Systems to offer Nexar, a mobile software product, to the North American marketplace. This digital solution makes inspections easy to conduct and their results easy to track. The software was created to manage, track and record field inspections in hazardous locations.

Nexar is a cloud-based field management solution that uses digital technology to mobilise inspectors and field workers. This software improves your operational management and reporting, unifying data management from field to office.

In sum, Nexar allows the energy & hazardous locations industries to:

- conduct inspections in high-risk environments with an easy-to-use handheld device

- manage and deploy a Risk-Based Inspection (RBI) strategy

- access accurate data for real-time decision-making and improved data management

- increase the efficiency of inspections by reducing the time and costs related to them

- comply with IEC 60079, NEC 500/505 and ATEX Directives

- integrate inspections with existing Enterprise Resource Planning (ERP) systems

- facilitate problem identification before failures become catastrophic

- easily generate tailored, error-free reports that provide you the data you need

Nexar software is intuitive. It “optimises operations, from inspections and maintenance to materials and logistics”. Teams onsite and offshore work together through mobile apps on Windows/Android/IOS platforms or online on your desktop. Therefore, support is provided to both onshore and offshore teams, resulting in more efficient and productive decision-making. Using this software improves overall employee engagement, productivity, attention to detail and, most importantly, safety.

Some of the clients using this software as a solution to the inspection and maintenance of electrical equipment in Hazardous Locations:

For more information or to get a demo of the software, please contact us at info@hazcon.com

Request a Consultation

Complete the form below to get started.