Interchangeable Installations of Class/division vs Zone System-certified Products in Gas Explosive Hazardous Locations

Manufacturers of electrical equipment seeking North American certification may choose either Class/division marking or Zone marking. The Zone and Division systems of area classification are deemed to provide equivalent levels of safety. However, the correct installation of the products is required.

Some manufacturers elect to get dual markings (both Class/division and Zone markings) so that the product may be installed in both Division and Zone hazardous areas in North America. Dual marking helps to make products more competitive, but there are additional technical requirements and rules and procedures to follow.

These rules are all outlined in the Standards related to hazardous locations. The requirements related to the installation of hazardous location products are found in Canada in the Canadian Electrical Code (CEC) and in the US in the National Electrical Code (NFPA 70). They are very precise, due to the hazards involved. (Note: The main reference can be found in the CEC Code Table 18 for installation in Canada and Sections 500-506 for installation in the US.)

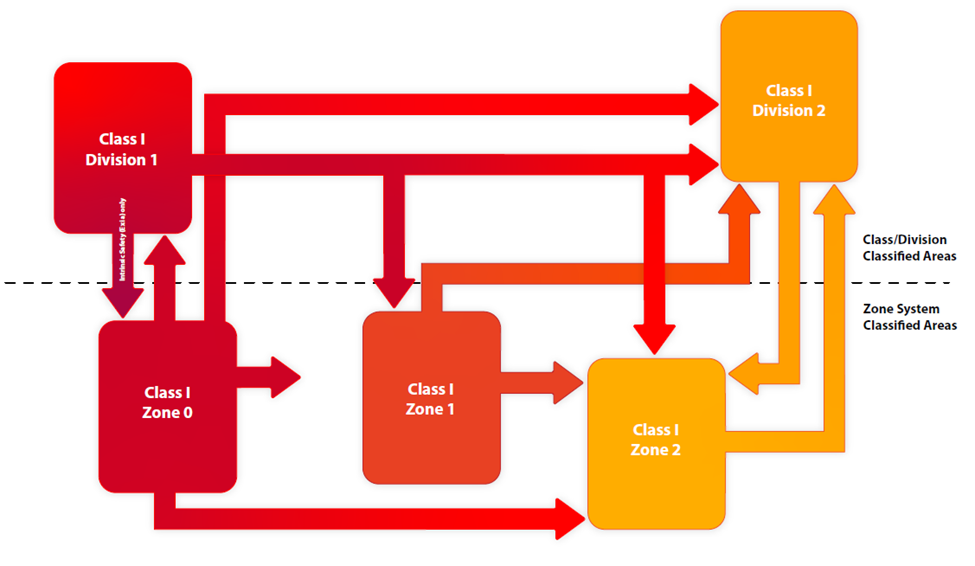

When the product has only one marking (Class/division or Zone marking), the question arises as to if this product may be installed in a differently classified area – one that differs from the product’s original marking. An example is an installer wanting to install a product with Class/ Division marking in a zone classified area. Hazcon has created the following schematic to show the relation between the two different classified systems for products approved for use in gas explosive atmospheres.

By following the direction of the arrows in this schematic, you can see that it illustrates the following:

Class 1 Division 1 Products:

- May be installed in Zone 0 (only if the protection technique is intrinsic safety; in other words, only intrinsically safe products (Ex ia) can be installed in Zone 0)

- May be installed in Zone 1

- May be installed in Zone 2

- And may also be installed in Class 1 Division 2

Class 1 Division 2 Products:

- May NOT be installed in Zone 0

- May NOT be installed in Zone 1

- May be installed in Zone 2

- And may NOT be installed in Class 1 Division 1

Zone 0 Products:

- May be installed in Division 1

- May be installed in Division 2

- May be installed in Zone 1

- May be installed in Zone 2

Zone 1 Products:

- May be installed in Zone 2

- May be installed in Division 2

- May NOT be installed in Zone 0

- May NOT be installed in Division 1

And finally, Zone 2 Products:

- May be installed in Division 2

- May NOT be installed in Division 1

- May NOT be installed in Zone 0

- May NOT be installed in Zone 1

Let’s explore why these rules exist.

- Division 1 and Zone 0 locations are similar, as may be seen in the following definitions. Products certified for these locations are protected against the highest level of risk, where an explosive atmosphere exists continuously.

Division 1: Division 1 means a location where an explosive atmosphere exists continuously, for long periods of time, or frequently.

Zone 0: Zone 0 is a location in which explosive gas atmospheres are present continuously or are present for long periods.

Class 1 Division 1 products are allowed to be installed in Class 1 Zone 0 areas, only if the product is intrinsically safe.

Class 1 Division 1 products using other protection techniques are permitted to be installed in Class 1 Zone 1 and Zone 2, or Class 1 Division 2, where the risk is lower. (Zone 1 is defined as a location in which explosive gas atmospheres are likely to occur in normal operation; or the location is adjacent to a Zone 0 location, from which explosive gas atmospheres could be communicated.)

Similarly, products certified as safe to be installed in Zone 0 may be installed in Class 1 Division 1 or 2, where the risk is lower.

- Division 2 and Zone 2 locations are similar, as may be seen in the following definitions.

Division 2: Division 2 means a location where an explosive atmosphere does not exist under normal operating conditions (but, if does occur, it will persist for a short period only), could certainly exist, and frequently does, given any abnormal operation such as repair or maintenance activities, accidental rupture of a vessel or container or failure of a ventilating system. Division 2 is the area immediately adjacent to a Division 1 location.

Zone 2: Zone 2 is a location in which explosive gas atmospheres are not likely to occur in normal operation and, if they do occur, they will exist for a short time only; or the location is adjacent to a Zone 1 location, from which explosive gas atmospheres could be communicated, unless such communication is prevented by adequate positive-pressure ventilation from a source of clean air, and effective safeguards against ventilation failure are provided.

Products certified as safe to be located where the degree of risk is highest (Division 1 or Zone 0) are therefore safe when located in Division 2, Zone 1 or Zone 2, where the risk is lower.

On the other hand, products certified as safe for Division 2 or Zone 2 cannot safely be installed where the risk is highest (in a Division 1 or Zone 0 or Zone 1 location). In the Zone system, products marked Class 1 Division 2 are only permitted to be installed in Class 1, Zone 2 (as well as Class I, Division 2).

When products with a higher level of safety are to be installed in a lower level of classified area, it’s important to maintain all the field wiring requirements of the original marking, even if the product is installed in a lower level of risk. An example of this is a Class 1, Zone 1 product, which is permitted to be installed in a Class 1, Zone 2 location. The product must be installed as per the requirements for Class 1 Zone 1.

Request a Consultation

Complete the form below to get started.