Understanding New Requirements of the Standard IEC 60079-11: 2023 Ed. 7

IEC 60079-11, Equipment protection by Intrinsic Safety (“i”) is the Standard that specifies the design, construction and testing of intrinsically safe apparatus intended for use in explosive atmospheres. It also applies to associated apparatus intended for connection to intrinsically safe circuits which enter such environments.

Intrinsic safety is one of the protection techniques used to protect electrical equipment used in hazardous locations. The effectiveness of intrinsic safety relies on the fact that the electrical and thermal energy available for ignition is restricted to a level below that which may cause an ignition. Electrical products that comply with the Standard related to this protection technique are allowed to be installed in Zones where the greatest risk of ignition exists – Zone 0 and Zone 20 (where an ignitable/explosive atmosphere is present continuously or for long periods of time), as well as locations that require less stringent protection (Zones 1, 2, 21 and 22).

Standard IEC 60079-11 was updated in January 2023. The new edition of IEC 60079-11 (Ed. 7) replaces the previous edition.

| Previous Edition | New Edition |

| IEC 60079-11:2011 Ed. 6 | IEC 60079-11:2023 Ed. 7 |

The Impact of Changes to Standards

Any changes to Standards require that manufacturers understand them and their impact on:

- New products, perhaps even at the design stage, which are not yet certified

- Products certified using the previous version of the Standard and that are already installed and being used

- Products whose design was already certified using the previous version of the Standard and which are yet to be built

Products whose design was already certified using the previous version of the Standard and which are yet to be built require the attention of the manufacturer, as the following table illustrates!

| PRODUCT | IMPACT |

| New products, perhaps even at the design stage, which are not yet certified | Naturally, new, uncertified products must comply with the new version of the Standard. |

| Products certified using the previous version of the Standard and that are already installed and being used | It is understood that changes should not normally have an influence on equipment already placed on the market. |

| Products whose design was already certified using the previous version of the Standard and which are yet to be built | These products need to be assessed and evaluated against the new edition. This is called a gap analysis – an assessment that takes into account the differences between edition 6 and 7 in this case. Depending on the construction of the equipment, changes to the product design may be required to ensure compliance with the new edition. |

A gap analysis examines the previously certified product’s ability to conform to the requirements of the new edition, given the major technical changes in the new edition.

Types of Changes Made to Standards When They are Revised

There are three types of changes made when Standards are revised:

- Minor and editorial changes (these changes are meant to clarify existing requirements but do not represent any significant technical change). In this case, any changes to technical requirements are considered minor and may even be a reduction to the level of the existing requirements.

- What are called “extensions”, which add new or modify existing technical requirements in a way that new options are given without increasing them. Requirements that are defined as extensions apply only to new products and do not need to be considered for previously certified products.

- Major technical changes (additional requirements or an increase to the level of the existing requirements). These changes have to be considered for products previously certified. These changes are the focus of a gap analysis!

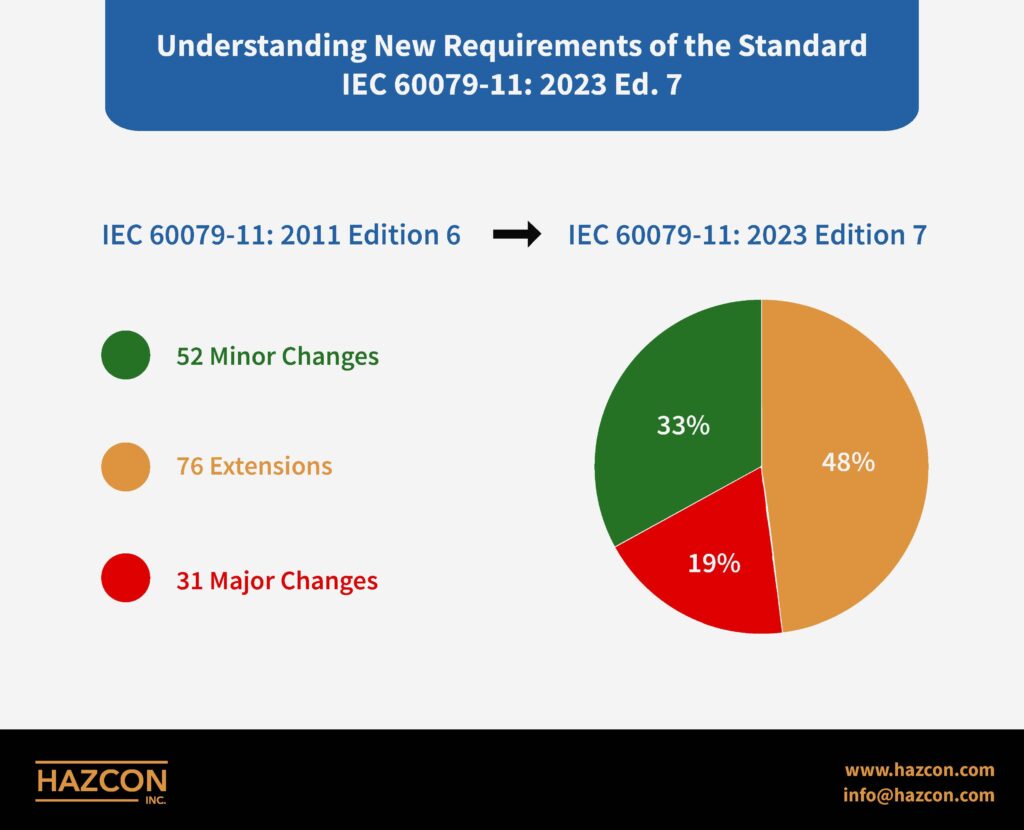

Changes in Standard IEC 60079-11: 2023

Edition 7 of IEC 60079-11: 2023 involves a total of 159 changes: 52 that are minor and editorial (33%), 76 that are extensions (48%) and 31 that are major technical changes (19%).

Gap analysis for products that conformed with IEC 60079-11: 2011 Ed. 6 focuses on these 31 major technical changes, each one of which may have multiple requirements. These major technical changes are very specific in their application: they apply to products with a specific marking (Ex ia or Ex ib, for example), a specific Group (Group III (dust) for example) or having used specific devices or means on which intrinsic safety depends (supercapacitors, fuses, or encapsulation, for example).

Changes that Relate to the Means Used to Achieve Intrinsic Safety and Specific Components on which Intrinsic Safety Depends

Products that use the intrinsic safety protection technique may have achieved intrinsic safety through a variety of means and may involve various different components. Major technological changes affect them in different ways. Here are a few examples of the major changes to the Standard that relate to the means by which intrinsic safety is achieved and some specific components on which intrinsic safety depends.

- Some additional requirements for encapsulation

- The effects of mounting conditions of the component and the consideration of their service temperature

- Thermal assessment for wires and PCB tracks based on the analytical techniques’ method

- Evaluation of circuits in which intrinsic safety depends on the operation of controlled semiconductors

- A change to the open circuit failure mode of conductors, connectors, and PCB tracks

- New requirements for earthed metal parts and isolated circuits

- Changes to components used to protect against polarity reversal connection

- New requirements for failure analysis of integrated circuits, semiconductors, and programmable components – e.g., microcontrollers, microprocessors, programmable logic controllers

- New consideration for spark ignition testing for an inductive circuit

- New requirements for fuses

- A change to the failure mode of resistors

- New requirements for supercapacitors and additional testing

- Additional testing for cells and batteries

- Additional requirements for transformers

- Additional requirements for relays

- Introduction of thermal devices and their safety requirements

- New requirements for infallible connectors and PCB tracks

- New requirements when reduced separation rules are applied

- Changed requirements related to infallible galvanic isolation between the coil and the contacts of relays

Some Changes Apply Only to Products in Specific Hazardous Environments

Some changes apply only to products certified as Ex ic (Zone 2) for example:

- New requirements related to failure of separations and subsequent failure of components for spark ignition assessment

- Changes to the rating requirement for safety components

- Consideration of ignition risk for fuses when their opening is an expected occurrence

- A change to the requirements for mains-powered associated apparatus

- Additional testing of transformers

Some changes apply only to products in a specific Group (Group III Dust Explosive areas for example). Examples are these:

- Changes to the enclosure ingress protection rating for Group IIIC products

- A change in testing for cells and batteries

- New requirements when reduced separation rules are applied

Hazcon Can Help!

These few examples illustrate the fact that manufacturers need to familiarize themselves with the major technological changes that affect their products! And then do the work necessary to achieve compliance with the new edition of the Standard!

At Hazcon, we can conduct a gap analysis assessment for your product against the new edition of the Standard (IEC 60079-11 Edition 7) and identify the complaint and non-compliant elements. We will provide recommendations on how to bring the non-compliance into compliance as per the requirements of the Standard.

We will give you a full assessment report including a complete checklist of compliance of your specific product with the new Standard . And we will help you obtain your certificate as per the latest edition of the Standard in an efficient way.

We welcome your inquiries about this, and any other issue related to certification of electrical devices in hazardous environments. Feel free to email us at info@hazcon.com.

Request a Consultation

Complete the form below to get started.